Order 3 Samples – Pay £8.99 delivery now, get it refunded when you place your order.

Learn more

This guide is designed for homeowners and installers. It outlines the types of stains and blemishes that commonly affect natural stone paving, showing possible causes and our recommended solution to remove the staining where possible.

Possible Causes

Fallen leaves, berries, petals, bird faeces etc will stain paving as they break down if not removed.

Solution

Sweep off all leaves, petals, berries etc on a regular basis. For any garden staining use Pavestone Patio Cleaner or for more stubborn stains apply Pavestone Black Spot and Algae Remover.

Possible Causes

Paving should be cleaned regularly. Poorly drained and shady/damp site conditions contribute to the growth of algae and lichen on paths and hard surfaces.

Solution

Possible Causes

Lime bloom coming through the paving from the cement-based mortar bed. This is a natural phenomenon and can happen at any time, however, it is more common when any form of void bedding has been applied. Look for sporadic staining.

Solution

Salts generally dissipate over time however you can use Pavestone Cement and Residue Remover.

Possible Causes

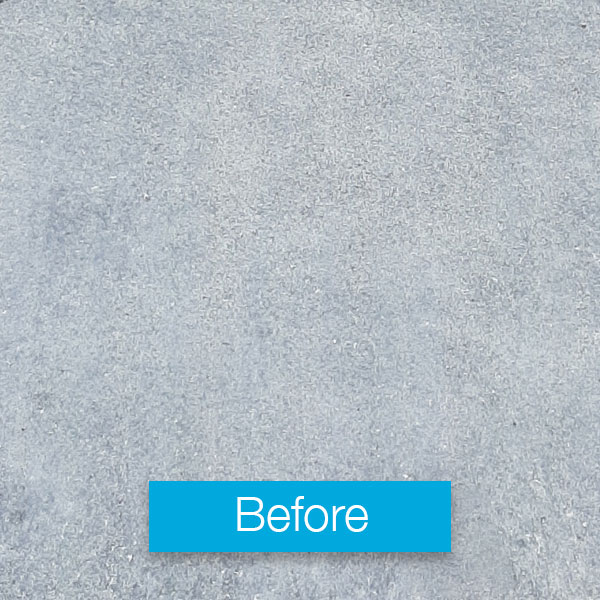

After 2-6 months of being out in the open, exposed to UV light, slightly acidic rainfall and with natural weathering the Black Kadapha Limestone starts to fade to grey.

Solution

If you wish to bring the colour of Kadapha Limestone back to black you can apply 2 coats of Pavestone Black Stone Rejuvenator and Sealer

Jointing Compounds can leave a residue of resin on paving after installation, especially in extremely hot weather, but this will generally disappear over time. If it stays on for a prolonged period the Pavestone Resin Residue Remover can be used to remove it.

Sometimes Jointing Compounds can show signs of cracking. Generally, the causes are that the compound has been installed too shallow, too narrow, not been mixed correctly, not ironed in or a combination of these.

When Jointing Compounds have not set after a few days it is more likely that the compounds have not been mixed correctly or it has been applied in the wrong weather conditions.

In some cases, sealing Natural Stone is not necessary.

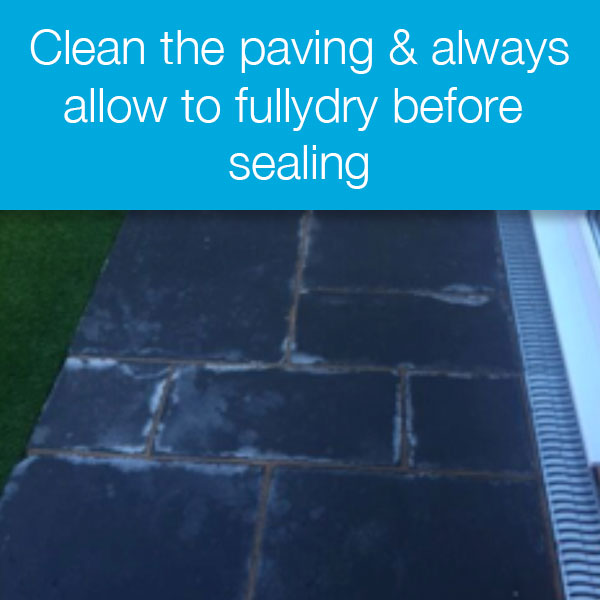

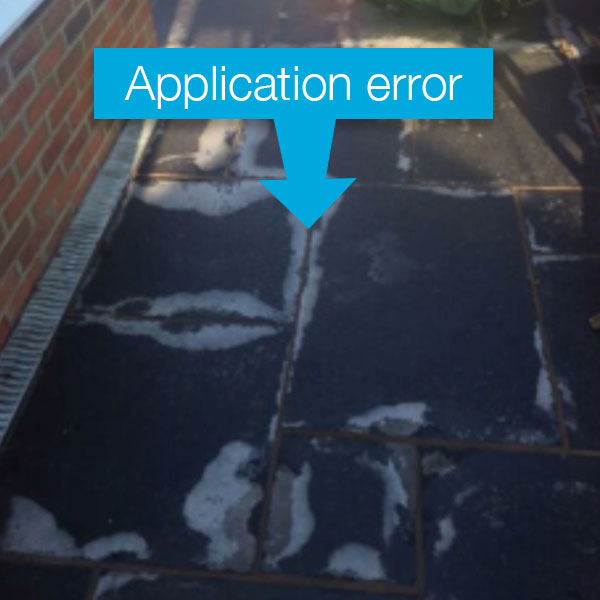

It is a personal preference of the consumer whether they want to enhance the colour of their patio or just protect the paving from staining. If you intend to use a sealer, you must adhere fully to the product instructions on the packaging.

Moisture on the surface, within the joints or even a bit of damp within the paving itself, can cause some sealants to turn 'milky', effectively ruining the finished appearance. Those sealants sold as suitable for all surfaces (the jack-of-all-trades) tend to be more prone to this than some of the higher-end quality products.

The paving should be clean, dry, free from dust, detritus and organic material (weeds, mosses, algae, etc).

A small area must always be tested first.

Pavestone have a range of water-based, breathable, impregnating sealers that can be used straight after laying as long as weather and site conditions allow. Prior to sealing always condition the paving by cleaning with Pavestone Patio Cleaner. This will also open the pores of the stone, enabling the sealer to penetrate deeper into the paving.

Pavestone Natural Finish Stone Sealer

Possible Causes

Iron Pyrites - blooms of rust coming from iron deposits within the natural stone or deposits in sharp sand/mortar mix.

Solution

Application of Pavestone Rust Stain Remover and Pavestone Iron Stain Remover.

Iron Stain Remover (blooming)

Removes rust breakouts, rust discolouration, cement and mortar stains from ferrous hard stones. Ideal for lighter tone stones such as light grey or Kandla grey sandstone.