When it comes to selecting the right patio paving for your garden, the material, size and colour of your paving slabs are all key features to think about from an early stage. This patio paving buying guide takes you through these considerations, but also lifts the lid on some less obvious criteria that could inform your purchase decision.

To help you find the ideal patio paving for your needs, this guide covers:

- Types of patio paving

- Paving slab colours

- Textures and finishes

- Antique style, weathering and ageing

- Indoor-outdoor living

- Paving slab sizes

- Patio paving patterns

- How much does patio paving cost?

- Durability

- Maintenance requirements

Use the links above to jump to the section you’re most interested in.

Types of patio paving

As you consider your options, the first decision to make is which type of patio paving to go for. There are three main patio paving materials used in the UK: concrete, natural stone and porcelain paving slabs.

Concrete

Concrete paving slabs are man-made. They’re produced by mixing cement with aggregates and pigments, which is either pressed or moulded to form a paving slab. The curing process that bonds the materials together can take many months and years to complete, even though the slab is ostensibly hard after 3-4 weeks.

Concrete is the weakest of the three paving materials, and consequently the slabs will be thicker to give them additional strength (30-50 mm).

Natural Stone

Natural stone paving is quarried from the ground and then hewn, cut and processed for the desired size and finish. Each stone slab is one-of-a-kind. Not only is there variation between the look and feel of every slab, but there are also significant differences in appearance and performance depending on which type of stone you choose.

If you opt for natural stone patio paving, there are plenty of different types to choose from:

The strength of natural stone paving depends on its type, with granite and slate being denser and stronger than sandstone and limestone. The thickness of stone paving slabs will be hewn or calibrated accordingly (18-25 mm).

Porcelain

Porcelain paving slabs are produced by firing kaolin clays in a kiln at temperatures that liquify the materials, which then become chemically fused to form a solid entity as they cool. These fused ceramic homogenous slabs are incredibly strong and durable. The vitrification (literally glass-like) process means that these slabs are non-porous,waterproof and largely impervious.

Highly versatile, porcelain patio paving can be engineered to resemble a range of different materials, including:

Porcelain is the strongest paving material, so it can be thinner than natural stone but still provide greater strength (10-20 mm).

Paving slab colours

When it comes to picking out patio paving, your choice of colour will be one of the most immediately noticeable features. The range of colour options available to you is determined partly by which material you choose.

Concrete paving slab colours

Concrete is usually a uniform, consistent colour at the point of manufacture. Whilst the original colour comes from a pigment additive, this may weather over time to provide some colour variation and character. There are also printed concrete paving slabs that have patterns and motifs such as mosaics.

The colour of concrete paving is much more uniform than the natural stone. So, if you want a consistent appearance and more uniform look, then concrete might be right for you.

Natural stone paving slab colours

Natural stone patio paving is available in a variety of colours:

- Sandstone has the greatest range, with light grey (Kandla Indian Sandstone), autumnal browns (Raj Blend) and sandy browns (Buff) being the most popular colours.

- Limestone also varies greatly in colour with light grey & gold (Abbey), grey-blue (Kota Blue) and charcoal (Kadapha Black) going across the tonal spectrum.

- Granite will tend to be silver grey to charcoal grey in hue (with sparkly flecks), whilst slate will be in the blue-grey to black range.

In terms of patterns, natural stone will have tonal changes, swirls, spots and flecks, seams and striations that could all make an appearance on the surface of the slab. You can even see fossils embedded in sandstone and limestone, as these are both sedimentary rocks created on the seafloor millions of years ago.

The character of natural stone slabs also changes when wet. After it rains, you often see the colours brighter and more vividly than before, with different hues and tones unlocked to the viewer. It is this unique variation and character that makes natural stone so appealing for patio paving.

Porcelain paving slab colours

Porcelain paving is printed before its protective glaze is added. So, its colour and pattern possibilities are only limited by the skill of the graphical artists and imagination of the manufacturer to create the slab.

You have lots of options when it comes to porcelain slabs:

- If you’re looking for stone-effect slabs, the printed graphics on porcelain paving are able to emulate the intricate character of granite, marble, quartzite, limestone, and sandstone.

- Wood-effect porcelain paving captures the grain and character of timber uncannily, even incorporating subtle textured relief to give the grain a more realistic feel.

- Porcelain also has the ability to provide original patterns that are not designed to emulate either stone nor wood.

Comparing the colours of paving slab materials

Below, we’ve summarised the different colour options offered by each paving slab material:

- Concrete patio paving tends to be fairly uniform in colour, although some printed slabs are available.

- Natural stone paving slabs offer a huge variety of different colours and patterns. Each slab also has its own unique character.

- There’s plenty of possibilities with porcelain patio paving, from wood- and stone-effect to unique patterns. Not all designs and patterns are of equal quality, so we always recommend getting samples before you buy.

Watch this video to see the natural colour variations and patterns you’ll find in Pavestone’s Light Grey Sandstone Paving:

Textures and finishes

Once you’ve considered the colour of your new patio paving, spend some time thinking about its texture and finish. Below, we’ve outlined your options when it comes to concrete, natural stone and porcelain paving slabs.

If there’s a particular texture or finish that you feel would be suited to your patio, get in touch and we’ll be more than happy to recommend paving slabs that meet your needs.

Concrete Paving

Concrete offers you a wide range of options in terms of texture and finish. This type of patio paving can either be wet-cast or pressed – and your choice of manufacturing method will have an impact on the texture of your paving slabs.

Wet-cast concrete paving is manufactured in moulds to allow different finishes and surface patterns to be created. Usually these are designed to mimic stone (a style referred to as “decorative concrete”). This type of patio paving often includes riven-effect gentle ridges on the surface, or the orange-peel like dimpling found on natural limestone.

You also have the option of choosing pressed concrete slabs. These offer a more uniform texture and finish. Pressed concrete paving tends to have straighter edges and near vertical sides, whereas wet-cast slabs will have a slight chamfer (angled) edge which is wider at the base to make removing them from their moulds easier.

Tanners Mill Antique-Style Concrete Flagstones (pictured below) show the rustic, weathered finish of wet-cast concrete paving.

Natural stone

There are four natural stone surface finishes:

- A riven surface is where the mason has hewn and then split the stone, which will leave small ridges on the surface (sandstone is the most common example). Explore our selection of riven natural stone patio paving to see how this looks.

- Light riven follows the same process, but the surface ridges are smaller. Some stone types like limestone have inherently smaller ridges, but this finish can also be produced by processing the slabs in a tumbler to soften and “weather” the stone. Take a look at our light riven natural stone slabs.

- A texture surface is achieved by machining the stone surface, leaving a granular or dimpled effect. This process provides a flatter surface with more grip, so is often used in higher foot-traffic areas and public spaces. We offer several different types of textured natural stone paving.

- The fourth finish is a honed surface, where the stone is milled to create a flat, smooth surface. You’ll find examples of honed natural stone slabs on our site.

You can see the riven surface texture of Pavestone’s Light Grey Indian Sandstone Paving Slabs in the image below.

Riven Kandla Light Grey Sandstone from Pavestone

In terms of edges, there are three options with natural stone:

- Hand-cut edges are exactly what the name suggests. The mason dresses the stone edge by hand to create the edge. These will be an inverted chamfer, with the widest point on the upper surface of the slab.

- Tumbled edges are hand-cut edges which have then been “tumbled”, a process designed to mechanically age and weather the slab so it looks timeworn and antique in appearance, with softer, rounded finishes on the edge profile.

- Sawn edges are the third type of edge that are generally available with natural stone. With this edge type, the slabs are table sawn in the factory to give them straight edges that are vertical. This allows sawn stone paving to be laid closer together than a hand-cut edge, so more contemporary narrow jointing (4-8 mm) is possible.

Porcelain

As porcelain paving is formed in moulds, surface textures that resemble riven sandstone, limestone orange-peel dimples and even granite’s granulation are possible. Porcelain also has the added advantage of anti-slip technology on its surface, offering better slip-resistance than other forms of paving.

Whilst there are some “antique” style porcelain slabs available, they are not as common and the choice of surface finishes is more limited than you’d find with concrete or natural stone patio paving. This is likely to change as porcelain manufacturers seek to provide a wider range of paving for more rustic and traditional properties.

Watch the video below to learn more about the variety of surface textures that are possible with Pavestone Dolomite Porcelain Patio Paving:

Comparing the finishes of materials

Unsure which type of material offers the texture and finish you’re after? Here, we’ve outlined the main differences between the three main patio paving materials:

- Concrete offers the best range of choices when it comes to finish and texture. You can choose between a pressed, smooth finish or a wet-cast stone-effect finish – and this material can capture the effect of different stone types.

- Natural stone can be engineered to offer a ridged or smooth surface, with straight or chamfered edges, depending on your preference. This tends to come at a price as they require additional production processes.

- Porcelain offers a range of different surface textures to mimic different stone types, with excellent anti-slip performance. That said, if you’re looking for a weathered or antique effect, you may be better off choosing a different material.

Antique style, weathering and ageing

Your new patio paving will last for years to come, so it’s worthwhile considering how your chosen material type will weather and age over time. If you’re keen on the idea of antique-style patio paving, you can also find pre-weathered concrete, stone, and porcelain slabs.

Concrete

Concrete colours will tend to fade faster than natural stone – it is unlikely to appear like it did on the day you laid it five years down the line. You can slow this process by treating the slabs with an appropriate sealer that will help protect them from moisture and UV sunlight bleaching.

Decorative concrete mould designs are often specifically made so the slabs appear more rounded and aged, like antique flagstones. This means you can more easily achieve the look and feel of time-worn and weathered paving without waiting for nature to take its course or sourcing reclaimed antique flagstones.

Natural stone

Natural stone will age and weather over time. Like concrete, it is also porous, so this patio paving material is susceptible to environmental conditions. Certain stone types such as Black Limestone (Kadapha) are well-known for the speed at which they fade in UV light. You can easily fix this with a UV protecting sealant if you don’t want to go for the weathered appearance that many people are looking for.

Looking for a more time-worn look and feel? Tumbled stone processing will give the stone that aged appearance, with the edges and surface being softer and more rounded. Alternatively, you can source reclaimed flagstones (although this can be pricey).

Porcelain

Porcelain is impervious to most environmental conditions and will not age or fade as stone or concrete might do. This is ideal if you’d prefer patio paving that will look similar to how it did when it was first installed in 10 years.

That said, if you are looking for something a bit more antique and distressed, it will need to already look like that when you install it! Look for “porcelain flagstones” or similar to find these antique-style slabs.

To the right, you can see the antique flagstone effect of Antico Quartzite Porcelain Paving

Indoor-outdoor living

Looking to create a seamless transition between your patio and indoor space? You could choose to match your indoor flooring with your outdoor paving, producing one continuous surface that connects the inside of your home with your terrace or patio.

This contemporary indoor-outdoor living style is best achieved with either natural stone or porcelain slabs. We would not recommend looking at concrete paving slabs in this role. This is primarily due to the inherent thickness of the concrete slabs. This makes them unsuited to underfloor heating and their thickness is awkward in most cases as they require an extra 30-40 mm of depth over 10 mm interior stone or porcelain tiles.

Indoor-outdoor matching porcelain tiles and paving slabs are becoming more common, but be aware these are two different products with different specifications and surface finishes. Exterior porcelain has to be suitable and have an R11 anti-slip rating to be considered safe for exterior use (where surfaces will be wet), so anti-slip technology measures needed to counter this must be used. When selecting matching interior and exterior tiles and pavers, review the anti-slip ratings:

- R9 – R10 – Interior use only (usually 6 – 10 mm depth tiles)

- R11 – R13 – Exterior use (usually 15 – 20 mm depth slabs)

Learn more about indoor-outdoor flooring in our blog.

Interior flooring with matching exterior paving (Dolomite)

Paving slab sizes

There are plenty of options when it comes to paving slab sizes, ranging from 100 x 100 mm right up to 2000 x 2000 mm to suit any preference.

The most common choices are:

- Square format 600 x 600 mm

- 3:2 ratio rectangular 900 x 600 mm paving slabs

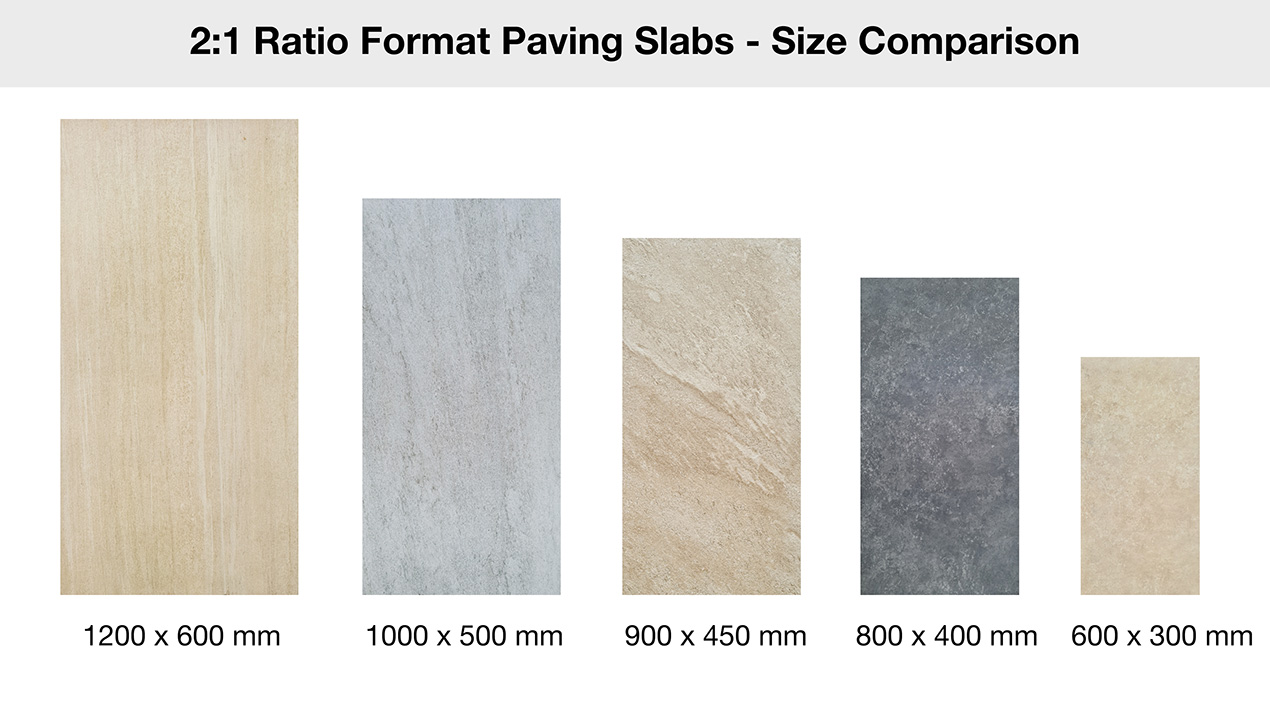

- 2:1 ratio rectangular format (1000 x 500 mm, 950 x 450 mm, 800 x 400 mm, 600 x 300 mm)

The inherent strength of the material will determine how large you can make the paving slab. The stronger it is, the bigger the slab’s lengths and widths can be relative to its thickness.

Due to the strength of the material, porcelain paving offer the largest format paving slabs available.

Below, we’ve outlined the paving slab sizes that are possible with different materials:

- Concrete slabs – rarely larger than 900 x 600 mm as the material is not strong enough (and these larger ones will tend to be pressed slabs with a 50 mm depth). With concrete, 600 x 600 mm is considered large.

- Natural stone slabs – you’ll find a reasonable selection of sizes, ranging from 100 x 100 mm to 900 x 600 mm (and even 1200 x 600 mm in some cases, although these are rare).

- Porcelain slabs – offers the widest range of possible paving slab sizes. This material is strong enough to support sizes of up to 2000 x 2000 mm, although 900 x 600 mm and 1000 x 500 mm are the most common sizes. Porcelain setts (100 x 100 mm and 200 x 100 mm) now becoming an industry standard too.

Large format (1200 x 600 mm) Discovery Origin Grande porcelain paving

2:1 Ratio Format Paving – Size Comparison

Patio paving patterns

When it comes to picking out the right patio paving pattern, you first need to decide whether to go for a uniform, single-size format or mixed-size paving (with a selection of squares and rectangles):

- Single size paving

- Mixed Size paving

If you’d like to create a consistent laying pattern, go for single-size slabs. A wider variety of patterns is sometimes possible with mixed-size slabs, although you’ll need to consult the laying patterns first.

All three types of patio paving material are available as single-size formats or as mixed-size. That said, mixed-size slabs are much less prevalent with porcelain paving at present, and you’ll most likely only encounter single size packs.

Below we’re placed single size paving next to a mixed size patio so you can see the difference between the uniform pattern of the former and the more irregular pattern of the latter.

Single-size Piazza Oasis Slabs on the left and the mixed-size Kandla Light Grey Slabs on the right.

Patio jointing styles

Your choice of jointing style will also affect the appearance of your patio paving pattern. For a contemporary aesthetic, you may want to consider narrow-jointed paving (where the slabs are positioned close together). On the other hand, wide-jointed paving tends to offer a more traditional look.

All three types of paving can be narrow-jointed (contemporary) or wide-jointed (traditional), but narrow-jointing will require the paving to have a straight or sawn edge that’s not chamfered, so the slabs can be laid near together (3-5 mm).

For more information about jointing, see are post How wide should the pointing on patio paving slab joints be?

A jointing compound is recommended for concrete and stone installations. Exterior paving grout is recommended for porcelain paving. However, a jointing compound can be used with porcelain, and will look okay if you’re using a traditional joint width.

Material choice and patio paving patterns

As you consider which pattern and jointing to go for, remember that the material you choose will impact the options that are open to you:

- Concrete paving – The edge profile of decorative concrete typically lends itself to wide jointing (the more traditional style). Pressed concrete will often have straight edges, and can be jointed narrower. Concrete slabs come in a wide range of size formats, with mixed size packs being common, giving you lots of choice when it comes to laying patterns.

- Natural stone – With plenty of size formats available, stone offers flexibility in terms of laying patterns. You can also choose between hand-cut chamfered edges or straight sawn edges, depending on whether you’d prefer contemporary narrow or standard and traditional wider jointing.

- Porcelain paving – Mostly sold in single-size packs, with limited options when it comes to mixed-size packs. If you choose this material, you’ll likely have to go for a more uniform paving pattern (or do a lot of cutting!).

How much does patio paving cost?

The cost of patio paving is not merely reflected in the price-per-metre-square of the slabs themselves. That is only one element amongst many which will determine what you end up paying. The main thing to factor in when buying patio paving is the installation costs (more on this below).

Paving slab costs

Generally speaking, you can expect to the price of your paving slabs to fall within these ranges depending on the material:

- Concrete: £25.00 – £45.00 m²

- Natural Stone: £25.00 – £60.00 m²

- Porcelain: £35.00 – £70.00 m²

Historically, concrete paving was the cheapest option. Then global trade allowed low-cost importation of natural stone from the likes of China and India, creating a large market in the last 30 years for the likes of Indian sandstone in the UK. Recent disruption to the global supply chain from Covid-19 has seen natural stone prices rise again, as shipping costs increase dramatically. This has equalised prices, bringing all three types of paving into a closer range.

Tips on finding the right price for paving slabs

It’s important to check carefully when comparing paving from different suppliers, as not all slabs are of equal quality. Here, we’ve provided some top tips to help you shop wisely:

- You typically get what you pay for because paving is made and supplied to a price within market conditions. A cheaper price is often a sign that the slabs are either of a lower quality or have fewer processes involved in their production.

- If the price of natural stone paving seems too good to be true, this is often because it has been sourced from lower quality quarries or taken from shallower seams of rock. It may look the same as sound stone to begin with, but will likely see more delamination, abrasions and cracking over time.

- Sawn edges, honed surfaces, tumbled ageing and depth calibration of natural stone all add to the cost. Expect to pay more for processed natural stone paving.

- Concrete and porcelain paving is man-made – below-average prices are often the result of cost-saving in the manufacturing process, which produces lower quality slabs.

Mosaic Arabica decorative printed concrete paving

Installation costs

The main cost of a new patio is the installation (materials and labour). The paving slabs will rarely be more than 20% of your total costs. Even if you end up spending double on the slabs, the impact on the cost would typically only add 10% to the project.

The key to keeping costs down is finding a good installer with a proven track record. Pay a little more to get the right installer – it will probably save you money as there will be no mishaps or errors to put right, and experts tend to work efficiently to their schedule too.

Your choice of patio paving material may also affect installation costs:

- Natural stone is the easiest material to cut and lay, with large slabs and few breakages. As a result, the installation should be quicker, keeping your costs down.

- Porcelain is much more difficult to cut, adding to your installation time and costs. That said, it is a tough material so breakages should still be few and far between.

- Concrete has more potential for breakages and often comes in smaller slabs, meaning it could take a little longer to cut and lay. Installation costs for concrete paving should be roughly the same as porcelain, but will often be more than natural stone for the same area of paving.

Durability

The porosity and hardness of the material will largely determine the durability of your patio paving.

Each different type of paving slab material has unique properties that affect the likelihood of it fading in the sun, weathering due to slightly acidic rain or eroding as a result of freeze-thaw cycles:

- Concrete is the least long-lasting paving material. With high porosity and weaker slab strength, concrete can crack more easily than other types (although you can help to prevent this by sealing the paving slabs).

- Natural stone tends to be more durable than concrete. That said, limestone can be susceptible to chemical erosion from rain and UV bleaching, whilst the surface of sandstone can delaminate (i.e. divide into layers) as a result of frost action.

- Porcelain is particularly hard-wearing and will typically last for a very long time. This material is not only waterproof and frost-resistant, but its pigments are also UV-protected to prevent fading.

We recommend sealing less durable paving materials such as concrete, limestone, and sandstone. This will help to protect them against the elements, reduce the likelihood of moisture related staining and frost action, and extend the lifespan of your patio paving.

Maintenance requirements

Maintenance requirements are an often-overlooked consideration when choosing patio paving. The porosity and hardness of the paving material will determine how easy or difficult it will be to maintain whilst preventing stains, scratches and the build-up of grime.

Concrete

Concrete requires the most maintenance due to its high porosity and weaker surface strength. This type of paving is more likely to absorb spills and grime than other materials, but it can be cleaned with special patio cleaning products.

We recommend sealing concrete paving slabs at an early stage to protect them. This will help to stop the material from scratching and staining over time, as well as preventing the formation of algae and black spots.

Care needs to be taken when washing concrete paving. We recommend that you do not use a pressure washer on concrete paving – this will likely damage the surface of the paving slabs (and can even remove the surface pigment).

Natural stone

Natural stone can require less maintenance than concrete, but this largely depends on the specific type of stone you choose. Granite and slate, for example, are fairly hard-wearing and will resist scratching and staining more than porous stone types like limestone or sandstone.

If you choose a more porous material, we recommend sealing it. The sealer will help to prevent erosion, delamination and algae formation.

You should use a priming slurry during installation. The priming slurry will ensure the slabs are properly stuck in place, and are less likely to become loose or rock, letting in water at the joints. The slurry also act as a membrane barrier on the underside of the slab, helping to reduce damp and blooming/staining from natural salts and minerals.

It’s also advisable to buy a specialised non-acid cleaning product for porous stone paving. These are designed to lift and clean deposits in the stone’s capillaries and micro-fissures without chemically damaging the stone.

Porcelain

Looking for low-maintenance patio paving? Then porcelain is your best option. This type of material is resistant to scratches and abrasions (but try to avoid dragging furniture or dropping garden tools on it, as it can still mark).

Porcelain is also the easiest paving material to clean. Because it is a vitrified (glass-like) homogeneous material, it is virtually impermeable/non-porous, so has no capillaries or micro-fissures that can get filled with grime, oils/fats, salts or minerals.

But just like glass, it can still be stained or become dirty via surface contact. A common surface stain will be tannin stains from decomposing and/or damp leaves, trigs, berries and nuts that have fallen on the patio. So simply brushing or blow these off the patio will mean it remains in pretty good condition.

If porcelain paving does become stained, then a patio cleaning chemical will usually resolve this issue easily, as you’re dealing with a surface stain, that’s not embedded in the slab itself.

Rounding up

This guide has taken you through the main things to consider when buying patio paving, from the different types of material available to the costs and the various looks you can achieve.

As you make your decision, remember that your choice of patio paving material is key. It’ll impact the options that are open to you in terms of colour, texture, finish, size and laying pattern. The durability and maintenance requirements of your new patio paving will also depend on its material.

If you’re unsure about which type of paving to buy or have any further questions, get in touch and we’ll be more than happy to help.